Lead Paint Removal

We all appreciate that paint removal is a messy job however when you are removing lead paint you really need to be aware of of the dangers involved as you try to minimize the mess!

We all appreciate that paint removal is a messy job however when you are removing lead paint you really need to be aware of of the dangers involved as you try to minimize the mess!

These are the guidelines as outlined in the Ministry of Health Guidelines that must be followed:

- Assume paintwork on pre-1980 buildings to be lead-based, unless it is proven otherwise by records or

- Use only workers who understand the hazards associated with lead-based paint and follow the procedures defined in the 2017 Guide to Hazardous Paint Management

Health Effects of Lead

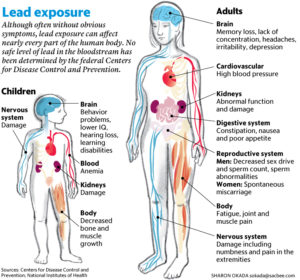

Lead is known as a cumulative poison. This means that it builds up in the body, and it takes some time for the substance to be excreted.

Absorbed lead is distributed to almost all regions of the body; therefore it is a substance that is capable of causing different types of harm. The brain is the most sensitive to lead poisoning, while approximately 90% of absorbed lead is stored in bone tissue.

With our increased knowledge of the hazards of lead exposure comes increased responsibility for identifying hazardous lead processes, and taking all practicable steps to eliminate, isolate or minimize these hazards both for you our client and for the team who work for us.

How is lead absorbed into the body?

- inhalation (for example, breathing in lead dust or fumes); or by

- ingestion (for example, eating products containing lead, or eating food, smoking cigarettes or biting fingernails after working with lead).

While it is important to control airborne lead dust and fumes, it is also important to make sure that people working with lead have good personal hygiene habits.

Even very small amounts of lead accidentally ingested with food or drink, smoking cigarettes or biting fingernails can increase a person’s lead uptake.

Lead Paint – Removal Risks

The use of wet scraping using paint strippers/solvents has proven to be one of the most popular, efficient and accepted methods of lead paint removal (refer ASNZS4361.1-2017 Guide to Hazardous Paint Management).

However in order for paint strippers/solvents to work so efficiently, softening the paint layer to allow removal, they must use chemicals. These chemicals pose serious risk of harm to the user. When selecting the paint strippers/solvent it is extremely important that the label is checked to insure that it DOES NOT contain methylene chloride or dichloromethane. Methylene Chloride (Dichloromethane) is an extremely efficient paint remover however when using this chemical even a cartridge-style or battery powered device used to filter the air will not be enough. Only a full-face respirator with a separate air supply, or exhaust ventilation to remove the fumes will provide protection.

Methylene Chloride (Dichloromethane) poses severe health risks and faces international ban as a paint remover. Refer:

httpss://www.epa.gov/newsreleases/epa-announces-action-methylene-chloride

https://www.hse.gov.uk/aboutus/europe/euronews/dossiers/dichloromethane.htm

When choosing the paint scraping method the person carrying out this work needs to mindful not only of the chemicals used but also that the lead scrapings are contained to prevent cross contamination of other areas including the soil.

Lead Paint – How to Remove it Safely

- Mechanical paint shaving process

- Chemical stripping (using solvents without methylene chloride also known as dichloromethane)

Our paint shaving equipment cuts the paint from the surface while sucking up the stripped debris into a HEPA vacuum system.

A solvent cleaning process is used for the remaining paint boarder (cutting in), around windows, doors, soffit and any other structural elements which may restrict the machines movement.

Lead Paint Removal – CSS using the dual method to save You time and money

CSS believes that our dual system has key advantages:

• Cut down on labour costs

• Reduce the use of solvents

• Minimise lead dust exposure

• Reduce the risk posed by lead paint debris on ground cover

• Minimize workers’ cross contamination through debris tracking on work boots

• Minimise post job clean up i.e. scaffolding

• Containment of lead paint particulates using extraction

Lead Paint Removal – CSS credentials

The CSS lead abatement team have all successfully graduated from the Master Painters “Management of Lead Based Paint Course” as fully certified Accredited Contractors – Lead Based Paint.